CMP is ranking number 1 in manufacturing technical body parts in France. It includes our operations :

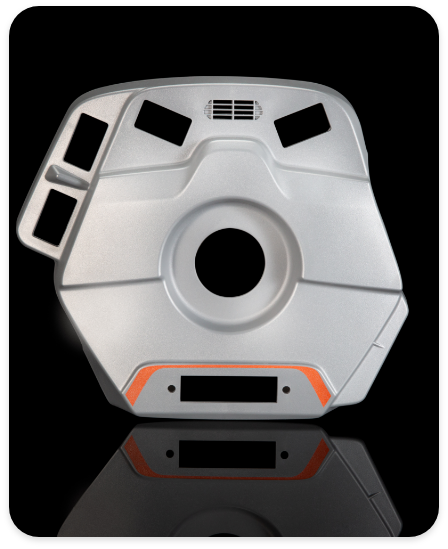

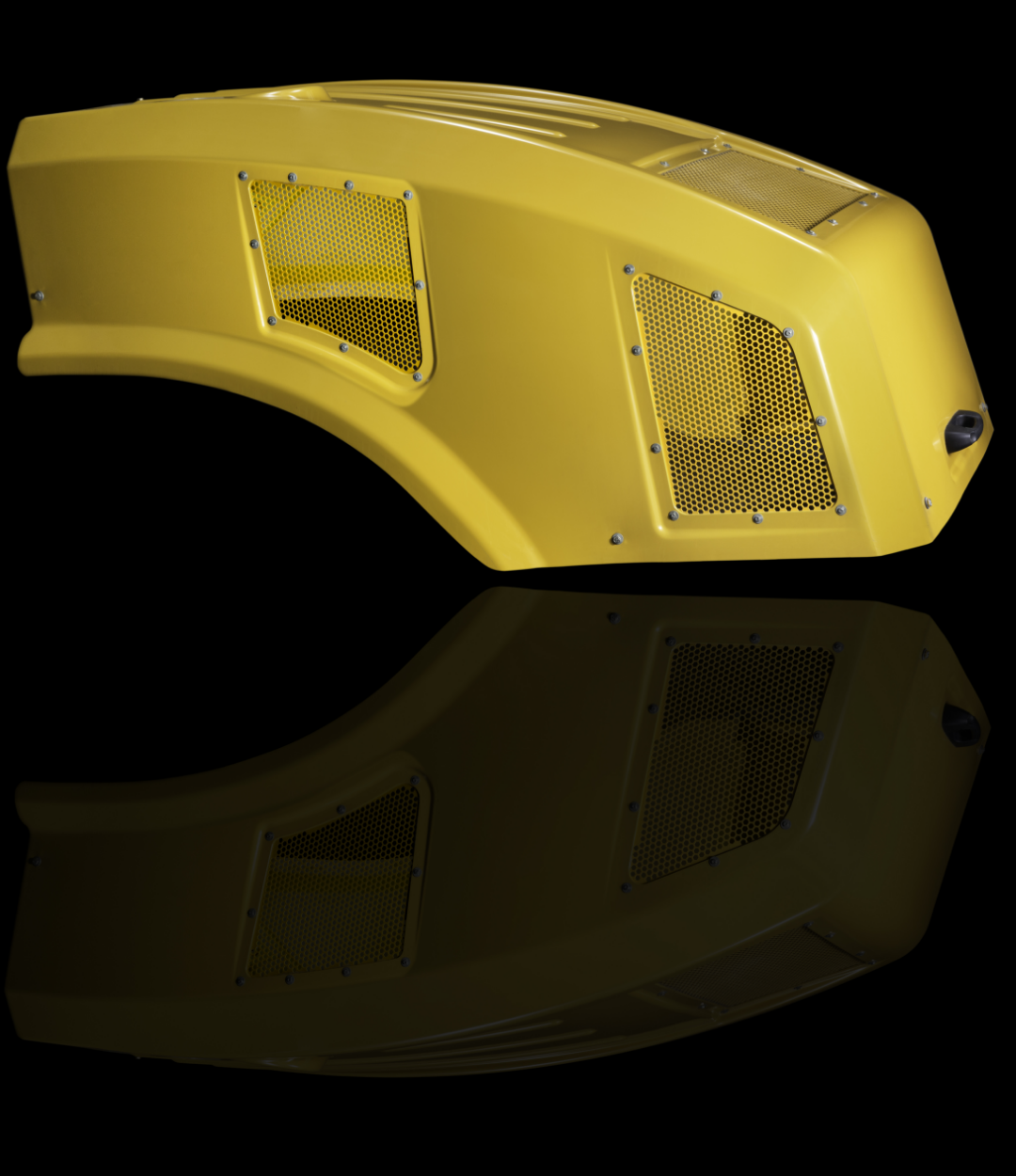

RIM (Reaction Injection Molding) pdcpd : transformation of thermoset material using RIM process. The body parts feature unrivalled impact resistance properties and are commercially available under the Mastershock® brand.

Vacuum forming, pressure forming and twin-sheet : Vacuum forming of sheets from thermoplastic materials (PP, ABS, PA, …) including partially regenerated materials.

CMP has been certified ISO 9001, ISO 14 001 and MORE label.

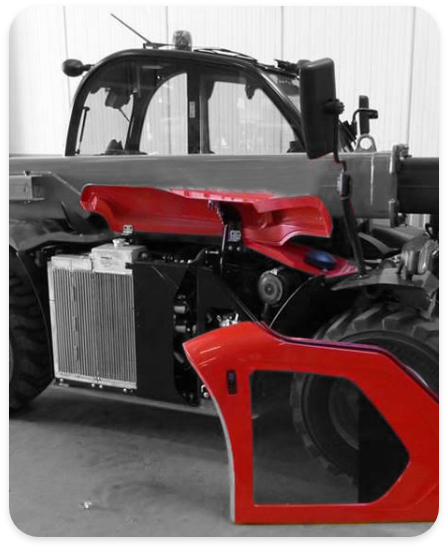

Markets

Courbis Master Parts

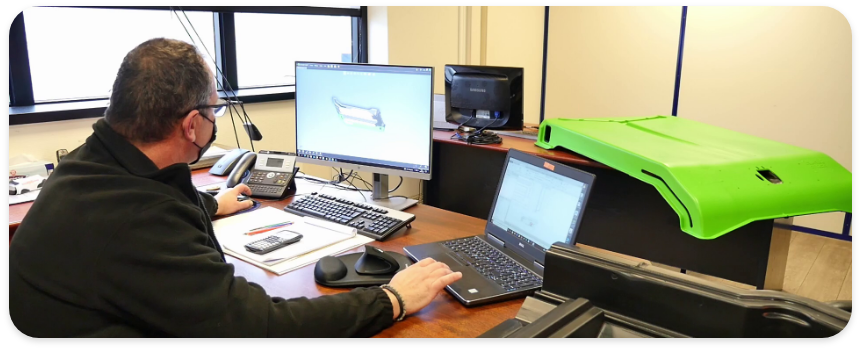

Design Office

Courbis Group’s strength : being able to carry out all your projects internally, from design to delivery. Our design office gathers engineers, project managers and designers. They are responsible for defining technical feasibility, calculations, selecting materials and supporting your projects with quality expertise.

Our production entities offer different technologies, and provide a tailor-made and quick solution to your needs.

Lab Center

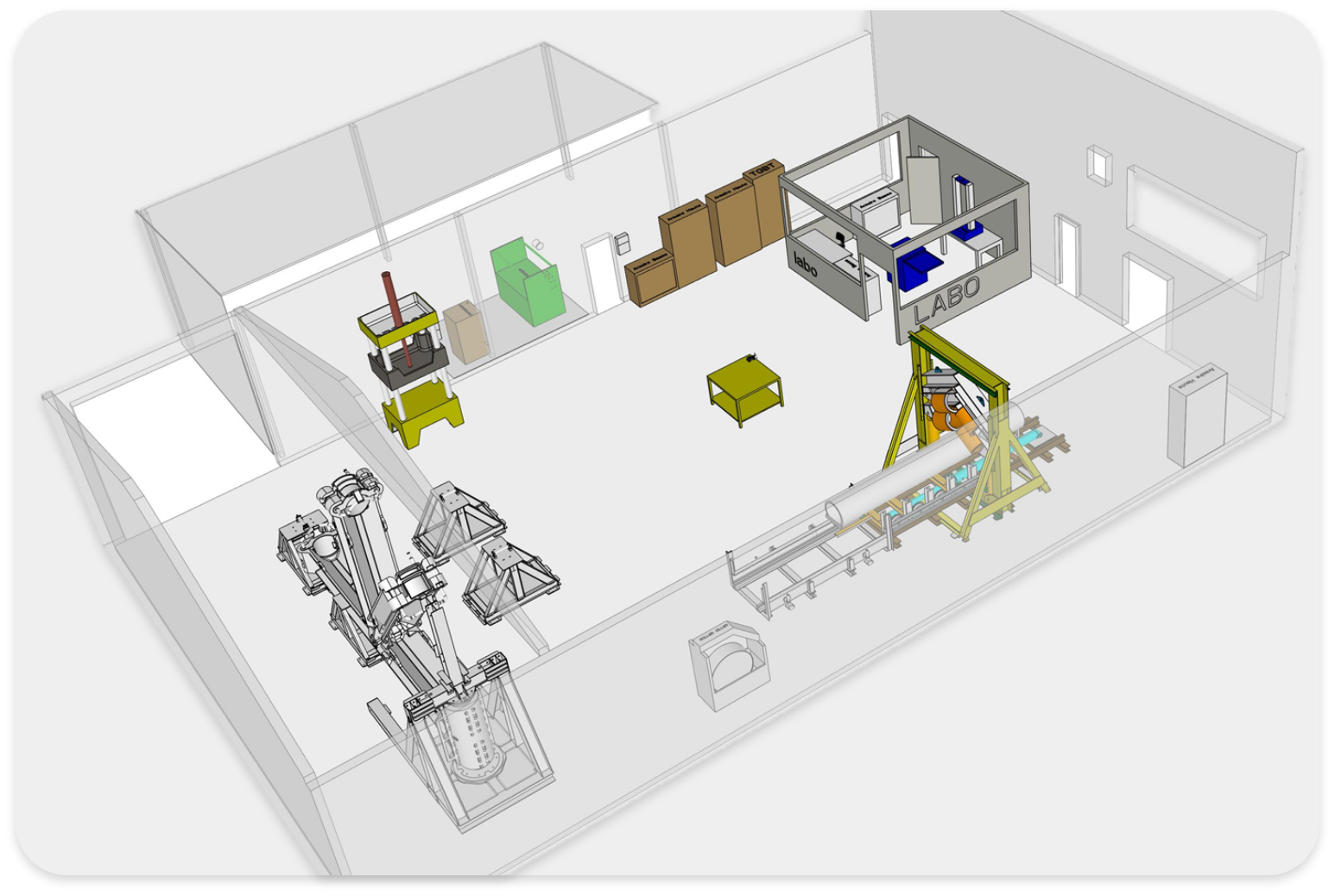

320m² test area, including 18m² of air-conditioned laboratory.

The Labcenter allows us to carry out material characterization and mechanical resistance tests both for internal development and for our customers.

Courbis Group is also : CSP which includes polyurethanes, silicons, polymers injection and mechanical machining operations located in France and in Slovakia.