Our Technologies

Our company’s unique strength : a technology portfolio at the service of our customers, for a turnkey solution !

Thanks to our international footprint (France, Slovakia, Brazil) we offer a flexible and reactive support to our customers’ growth plans and act as partners in their projects.

We support key accounts as well as SMEs (Small and medium-size enterprises) in their search for solutions. We are not only specialized in medium production runs, our process is also perfectly fit for prototype parts and medium size series.

Casting polyurethane

Pioneer of polyurethane casting in France.

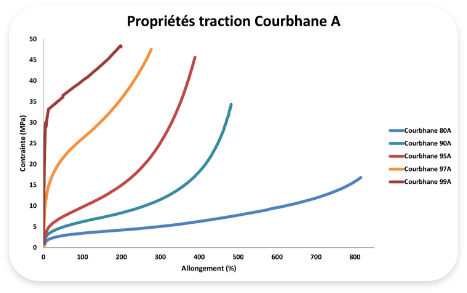

Through the casting process, the pre-polymer technology and molding method will ensure the expected properties of Courbis Polyurethanes Courbhane® are met :

• the usual hardness of our products ranges from 25 Shore A to 85 Shore D

• specific target properties: hydrolysis resistance, excellent behaviour under dynamic constraints, as well as resistance…

Development of new materials specifically suited to your requirements : anti-static properties, vibration damping performance…

Our lastest innovation CourbhaPure®, a moca-free standard Polyurethane brand, is combining state of the art durability and a green footprint !

Our process is very flexible, ideally suited to unique parts and medium size series.

> Resistance to abrasion

> General mechanical properties

> Load resistance

> Impact resistance

> Resistance to hydrolysis

> Resistance to oils

> High hardness

Application

Examples

Roller

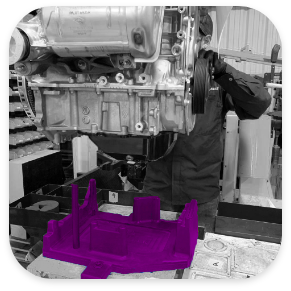

Engine support

Roller

Connecting rods

Stand by clamp (off shore)

Shroud (Off shore)

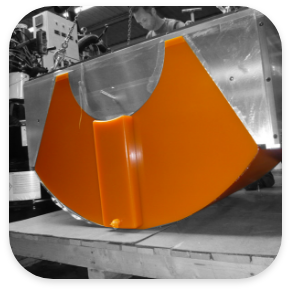

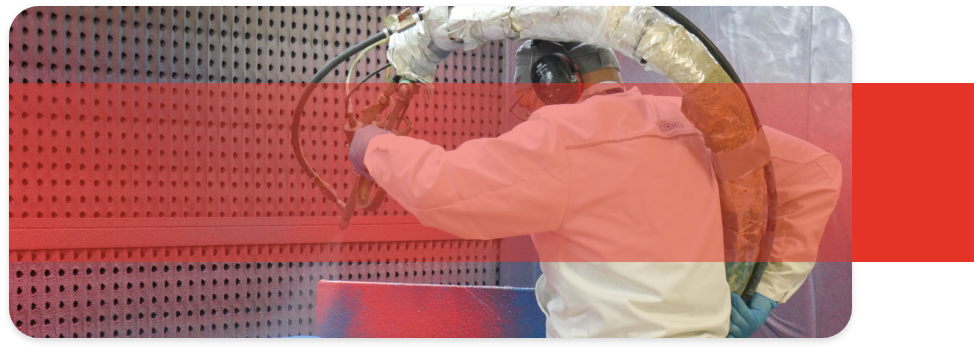

Sprayed Polyurethane

Thanks to Courbhane® quick polymerisation time, the projection process offers an elastomeric material which can be processed quickly on any part geometry :

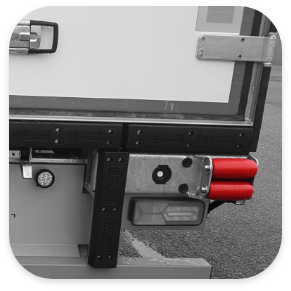

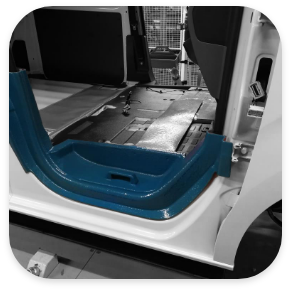

• Removable protection of fragile parts (automotive body panels, dashboards, airplane and helicopter parts, as well as elements for boats, rail, tractors, trucks, busses…) to protect parts during the assembly process.

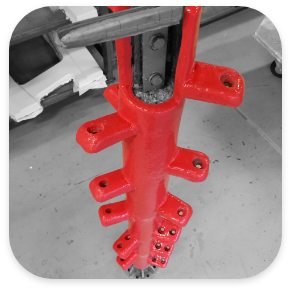

• Anti-abrasive coatings on tribofinition containers, concrete mixing equipment, ducts, conveyors, vibrating bowls, various mechanical parts and tools…

Our process is very flexible, and ideally suited to unique parts and small series.

Application

Examples

Airplane manhole protection

Door frame protection

Tablet for TGV bar

Mixer shaft

Tribofinition tank

Silicones

Courbis Coursil ® product range basically includes two types of silicones :

• RTV (Coursil S ® range) : silicones crosslinking at room temperature and used in a casting process = technical parts and semi-finished products.

• EVC (Coursil C ® range) : elastomers crosslinking in hot temperature and compression conditions = technical parts for significant volumes.

Silicone materials are dedicated to withstand high temperature around 180° minimum in continuous use, whilst keeping their outstanding properties regarding flexibility, chemical stability and electrical insulation...

The Coursil ® silicone range offers a wide variety of hardness, ranging from 6 Shore A to 70 Shore A.

We can develop some new materials specifically suited to your requirements.

Application

Examples

Compression membranes

- Energy

Plug

Interior and superior protections

Protections

Measurement instruments for drilling

Mechanics

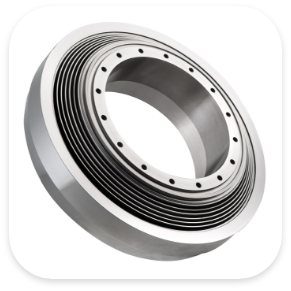

Specialized in mechanical engineering since 1964.

2 major developing core-businesses :

• Design and manufacturing of mechanical kits for COURBIS group

• Highly technical and value-added mechanical parts manufacturing

Know-how

> Cold deformation of metals

> Multi-axis machining: milling, turning, water jet cutting

> Machining of metallic materials (aluminum, stainless steels, steels, inconel and niobium)

> Machining of plastic materials from 25 to 99 shA

> Mechanical assembly

> 3D testing laboratory

Application

Examples

Mechanical assembly for vessels, helicopters

Stainless steel oil distributor

Equipped hardware

Water jet cutting

Machined PU part

Mold assembly

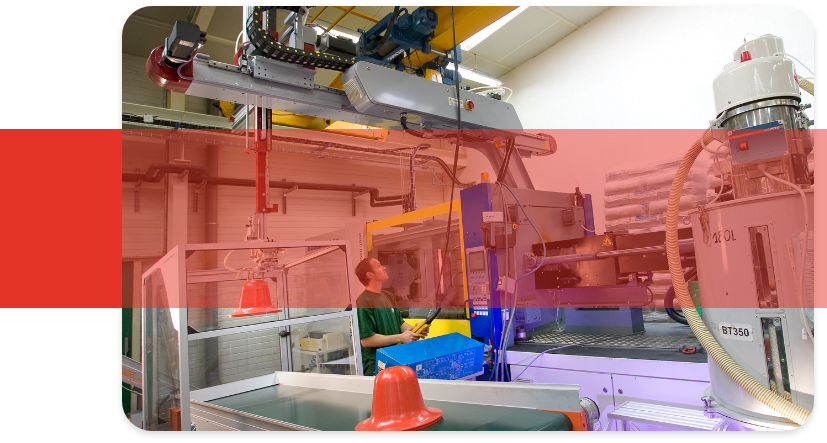

Polymer Injection

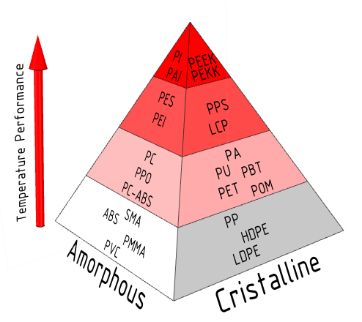

Processing of all thermoplastic materials (PE, PP, ABS, …) and technical polymers (PA, TPU, PEEK, PEI...) by injection technology.

This process is particularly suited for medium and large series.

From standard polymers to high performance polymers fitted to challenging environments.

Application

Examples

Gear box actuator

Industrial vehicle interior part

Orthesis

Missile body parts

Covers & vibration dampers

Bend restrictor (Off shore)

Groupe Courbis c’est aussi : CMP qui regroupe nos activités de RIM pdcpd, thermoformage, thermo-pression et twin-sheet.