Our Technologies

Our company’s unique strength : a technology portfolio at the service of our customers, for a turnkey solution !

Thanks to our international footprint (France, Slovakia, Brazil) we offer a flexible and reactive support to our customers’ growth plans and act as partners in their projects.

We support key accounts as well as SMEs (Small and medium-size enterprises) in their search for solutions. We are not only specialized in medium production runs, our process is also perfectly fit for prototype parts and medium size series.

Vacuum-forming

Processing of all thermoplastic materials (PP, ABS, PA, …), from 1 to 15 mm thick, by vacuum-forming, pressure thermoforming and twin-sheet :

• Heating up a polymer sheet according to a predefined curing cycle. The softened sheet will then be draped onto the mold to obtain the perfect shape after cooling

• Process adapted to small and middle size series

Advantages

> Cosmetic parts (including transparent)

> From prototype to mass production

> From small to very large MP format (400X400 TO 2500X1500)

> Recyclable raw materials

> UV resistance, fire and food standards, etc.

> Thermo-pressure: sharp angles, undercuts, guaranteed external geometry

> Twin-sheet: hollow and rigid bodies, overmolding of inserts

Application

Examples

Industrial vehicle

Health material

Military equipment

Vélib terminal

Aircraft equipment

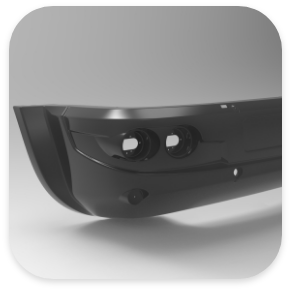

RIM pdcpd

French market leader in RIM (Reaction Injection Molding) PDCPD process, commercialy available under the MASTERSHOCK® brand.

PDCPD is a thermoset material manufactured thanks to the RIM process. Two components are being mixed to create an in-mould polymerization. MASTERSHOCK® products features unrivalled impact resistance properties and are suitable for the manufacturing of large parts.

Advantages

> Impact resistance

> Temperature ranges (-40°C +120°C)

> Tensile strength

> Chemical resistance

> Low density (1.03)

> Elasticity

> Freedom of design

> Large dimension parts

Application

Examples

Body parts for pulverization machine

Bumper

Roller hood

Mower deck

Beds and hoods of gutters

Courbis Group is also: CSP which brings together our polyurethane, silicone, polymer injection and mechanical machining activities, in France and Slovakia.